In parallel with our study department, TMP Industrie develops tooling, conducts fine-tuning, manages all modifications and their consequences in-house, and provides all maintenance. Adequate stock of standard spare parts is available for all tools.

We assume responsibility for the follow-up on all phases of tool construction and validation by our mold makers (France, Portugal and China).

TMP Industrie has the right industrial tool to guarantee the survival of your projects in mass production :

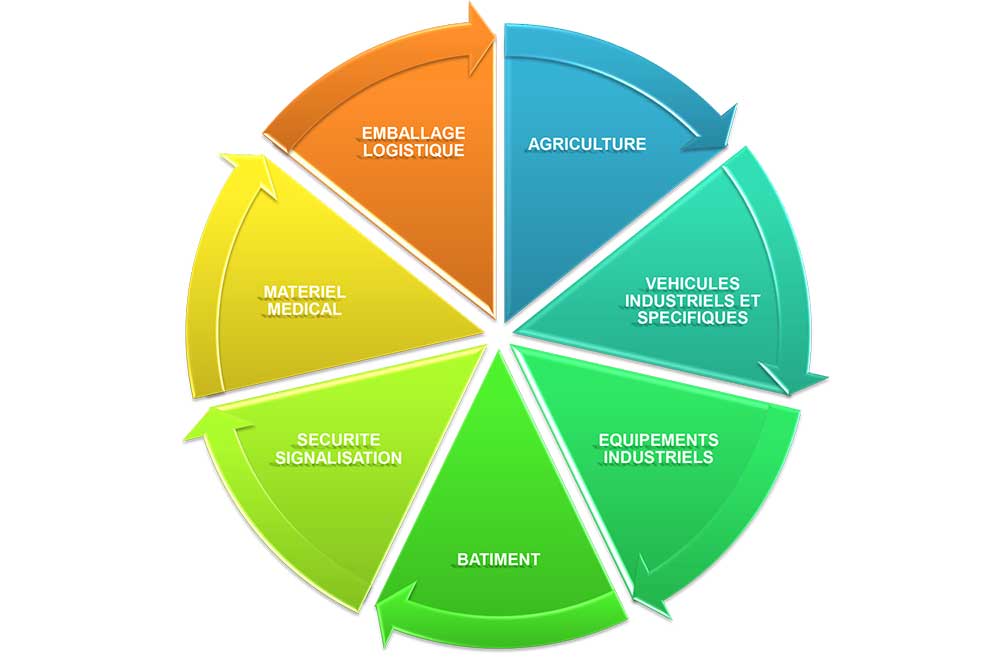

TMP Industrie has been forging its industrial experience for over forty years, in fields with very different requirements.

Our multiple developments and mass productions, carried out for customers in differing industrial sectors, have helped us to modulate our techniques over the years, gaining in flexibility and performance, and meeting numerous industrial challenges.